Geometric Steels manufactures a complete array of structural C and Z purlins, as well as girts for garages, industrial structures warehouses, as well as PEB in pans wherever sturdy, durable steel framing is needed. Produced using high-quality galvanized steel This is an integrated system that permits various design possibilities. Available plain or punched, purlins galvanized, and made using high-tensile steel to increase strength, less weight and a longer-lasting serviceable lifespan.

Geometric Steels offers the fastest service in town. Modern, state-of-the-art equipment permits not only speedier production as well as greater ability to accommodate your demands. A typical lead time is between 8 and 10 working days when the product is available. If the project is more extensive, additional time could be required.

Geometric Steels Purlin can be described as an extremely fast and simple-to-install system that was designed with the installation in mind. There are capsule-type holes or punches that measure 24 millimeter diameter This helps the installer install the purlin more quickly. Installation is simpler and more efficient for the rigger who operates from a distance away typically in stormy and challenging conditions. This saves time and money.

Geometric Steels' purlins are smooth, neat, and square. By any measure, they're high-quality products. There's no reason to accept round corners, inaccurate lengths, or purlins that are out of square for any longer. Get high-quality Geometric Steels purlins to complete your project.

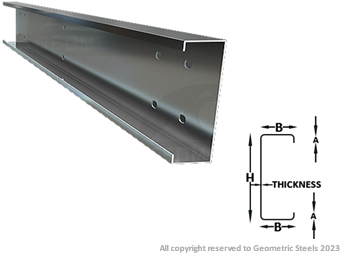

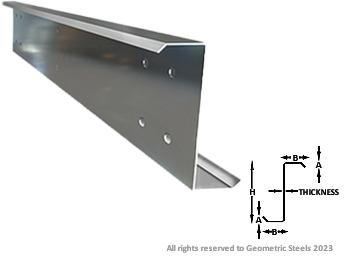

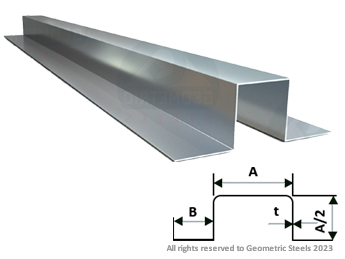

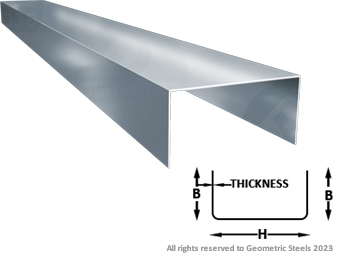

Our Products Geometric Steels manufactures an entire collection of C Z, C U , L , and Hat sections. The girts and the purlin are both offered for a variety of applications from 3 millimeters thick. Made from quality high-tensile galvanized CR & HR Steel. Geometric Steels Purlin and Girts can be delivered in plain or punched. This is a fully integrated system, allowing for flexible design options. Geometric Steels Purlins are constructed with high-tensile steel, which provides more strength, less weight and a longer lifespan.

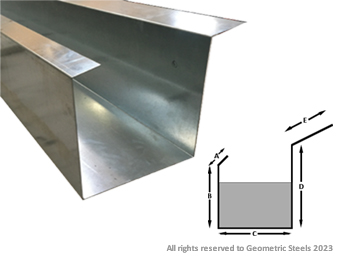

C Purlin is available in various sizes and strengths (Eg 240 Mpa (240 mpa), as well as 350 Mpa) to meet the design calculations of your construction.

Z purlin is a great product to provide large spans between the frame of the portal on your Industrial construction. Z purlin can be found in a variety of sizes and strengths to fit the specifications that you have for the building.

The hat Section consists of two flanges outward (the brim) and 2 vertical dimension (the edges that make up the sides of the hat).

The U section is widely employed for polyhouse and other applications that require specialization. This section is manufactured in state of the art plant located at Kurkumbh in 1.00 mm to 3.00 mm thickness, as per the requirement of the customer.

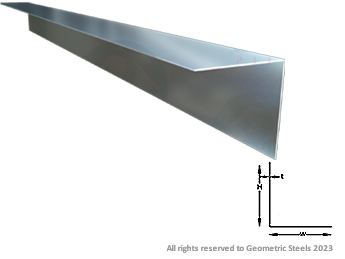

The L-Section's or L-angle’s capability to span lengths without the necessity of drilling on the site or cutting, as well as guaranteed dimensions and strength results in less weight and lower transport costs.

The Gutter system is among the most vital components of industrial roofing. If it's not done properly at the beginning. It's going to be a constant problem to maintain. Geometric Steels provides a variety of gutter systems based on the requirements.

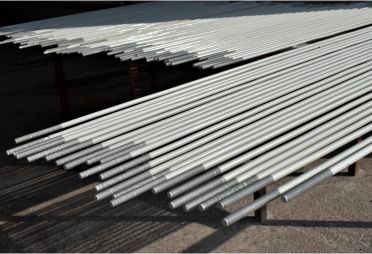

Sag Rod is a distinct type of rod. Sag Rod is completely different from the Turnbuckle Rod or Clevis Rod. It generally requires the passing through the members it is supporting like C and Z Purlins with 12mm-to-16mm diameters. Sag Rods serve as Lateral Supports for Girts or Purlins.