In industrial settings, effective gutter design and the integration of down-take pipes are crucial components for efficient water management systems. The right design ensures that rainwater is properly channelled away from buildings, preventing damage and maintaining structural integrity. This guide will explore the key considerations in metal gutter design, types of gutters suitable for industrial applications, and the essentials of down-take pipe design.

Effective Gutter Design

An effective gutter system is critical for managing water runoff from industrial roofs. Here are the primary considerations to ensure an efficient setup:

1. Sizing and Capacity

o Gutter Size: Selecting the appropriate size for gutters is fundamental. Industrial roofs typically require larger gutters, often 6 inches or more, to handle the substantial water volume resulting from large roof areas and intense rainfall.

o Slope: Proper slope is essential to facilitate water flow towards downspouts and prevent standing water. A typical slope of 1/16 to 1/8 inch per foot is recommended.

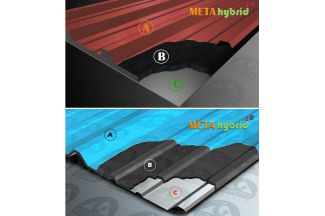

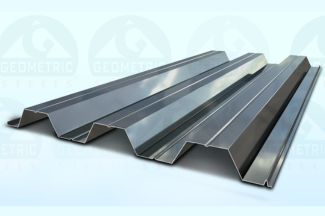

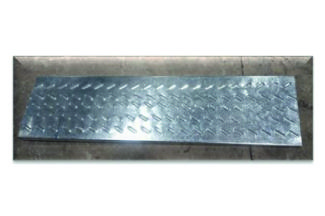

o Material: The choice of material is crucial for durability. Metals like galvanized steel, aluminium, and copper are ideal due to their ability to withstand harsh weather conditions and heavy water flow.

2. Joint and Seam Management

o Seamless Gutters: opt for seamless gutters to minimize the risk of leaks. These are custom-fabricated on-site to the exact length required, reducing the number of seams.

o Sealed Joints: When seams are unavoidable, high-quality sealants and proper joining techniques should be used to minimize leaks.

3. Debris Management

o Gutter Guards: Installing gutter guards or screens can prevent leaves, debris, and pests from clogging the system. This is particularly important in industrial areas prone to high debris accumulation.

o Regular Maintenance: Regular inspections and cleanings are necessary to ensure that the gutters remain clear and functional.

Types of Gutters

Choosing the right type of gutter is essential for efficient water management in industrial settings. Here are the common types of gutters and their characteristics:

1. U-Style Gutters

o Design: U-style gutters feature a flat back and bottom.

o Capacity: These gutters can handle more water than half-round gutters, making them suitable for industrial applications.

o Durability: Available in various materials, with aluminium and steel being common for industrial uses due to their strength and corrosion resistance.

2. Half-Round Gutters

o Design: Semi-circular in shape, half-round gutters are a classic design.

o Capacity: They handle less water than U-style gutters but are easier to clean and less likely to clog.

o Aesthetic: Often used in older or historic buildings but can be appropriate in industrial settings. Typically made from UPVC or PVC materials.

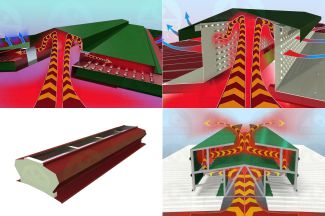

3. Box Gutters

o Design: Box gutters are larger, rectangular gutters often integrated into the roof structure.

o Capacity: High water capacity, ideal for large industrial roofs.

o Installation: Precise installation is required to ensure proper drainage and avoid water damage to the building.

Down-Take Pipe Design

The design of down-take pipes is crucial for directing water away from the building effectively. Key considerations include sizing, placement, and material selection.

1. Sizing and Placement

o Size: The size of down-take pipes should correspond to the gutter size and the amount of water they need to handle. Proper sizing prevents overflows and ensures efficient drainage.

o Placement: Strategically place down-take pipes at intervals that allow for optimal water flow. Typically, downspouts should be placed at every 20-30 feet of gutter length.

2. Material

o Durability: Use materials that can withstand the environmental conditions of the industrial site. Galvanized steel, aluminium, and copper are preferred for their strength and longevity.

o Corrosion Resistance: Ensure the material is resistant to corrosion to extend the lifespan of the system.

3. Installation Techniques

o Secure Fastening: Down-take pipes should be securely fastened to the building to withstand high water flow and wind conditions.

o Proper Angling: Ensure that the pipes are angled correctly to facilitate water flow and prevent blockages.

Advantages of Using Longer-Length Metal Gutters

Longer-length metal gutters offer several benefits that make them an ideal choice for industrial applications. By minimizing the number of joints needed, these gutters significantly reduce the likelihood of leaks, protecting the building’s foundation and walls from water damage. Seamless longer gutters also provide better structural integrity compared to multiple shorter sections joined together, reducing the risk of sagging and separation over time. This results in a more durable and long-lasting gutter system that requires less frequent repairs and maintenance, enhancing overall efficiency. Additionally, longer gutters allow for a more efficient and continuous flow of water, reducing the risk of blockages and overflows, which is crucial for industrial shades with large roof areas.

Furthermore, longer-length gutters offer aesthetic and cost-effective advantages. A seamless gutter system provides a cleaner, more streamlined appearance, which can be important for industrial buildings that wish to maintain a professional exterior look. While the initial installation of longer gutters may be more complex and potentially more expensive, the long-term benefits of reduced maintenance, fewer repairs, and less frequent replacements can result in overall cost savings. Custom fabrication to fit the exact dimensions of the industrial shade ensures a perfect fit and maximizes the efficiency of water collection and drainage. The high durability and strength of metal gutters, particularly those made from materials like aluminium, steel, or copper, make them capable of withstanding harsh environmental conditions better than other materials.

Longer-length metal gutters are highly beneficial for industrial roof guttering due to their superior performance, durability, reduced maintenance, and cost-effectiveness over time. They provide a robust solution for managing large volumes of water efficiently, protecting the structural integrity of industrial buildings, and enhancing their overall appearance.

By carefully considering the design, materials, and installation techniques for gutters and down-take pipes, industrial facilities can ensure effective water management and maintain their structural integrity. Investing in high-quality metal gutter systems tailored to the specific needs of industrial settings is crucial for long-term success and sustainability.

For more information about our industrial guttering solutions and to explore our full range of products, visit our website at www.geometricsteels.com or www.rooflab.in.